Jaw Crusher Mineral

.jpg)

Jaw Crusher TAYMACHINERY

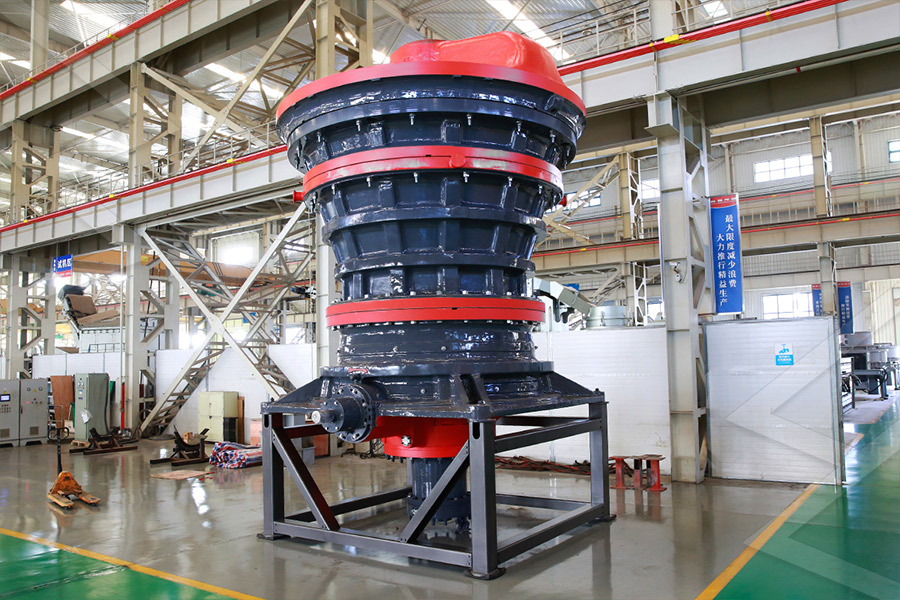

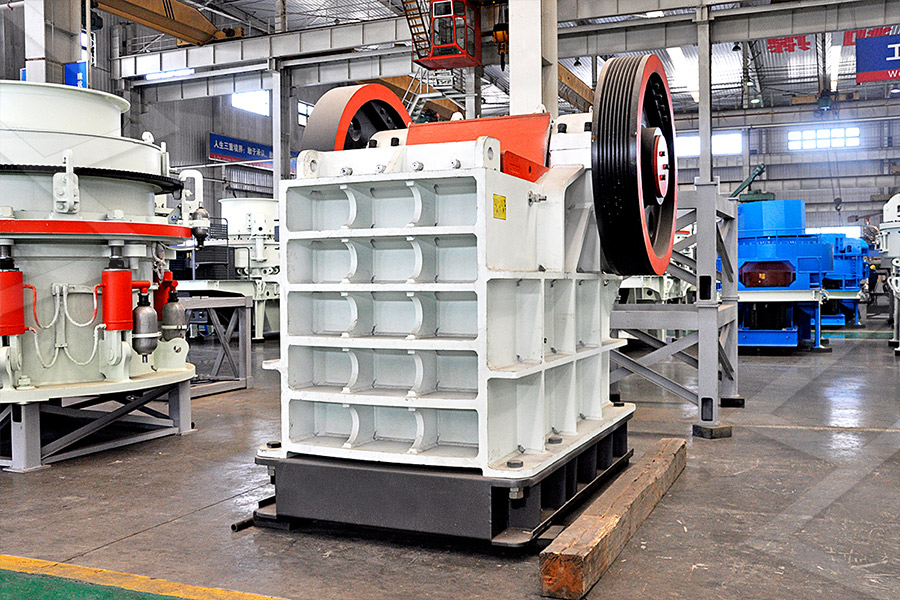

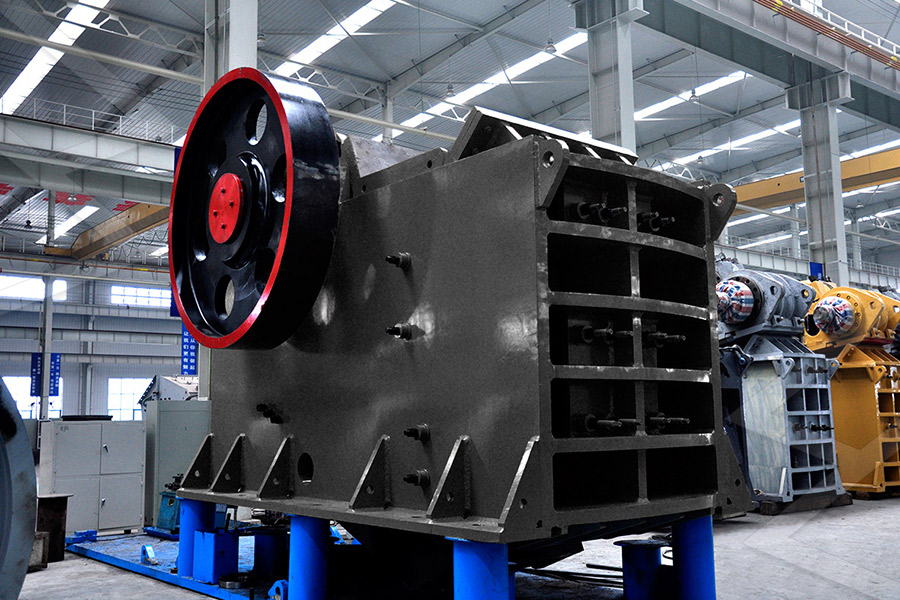

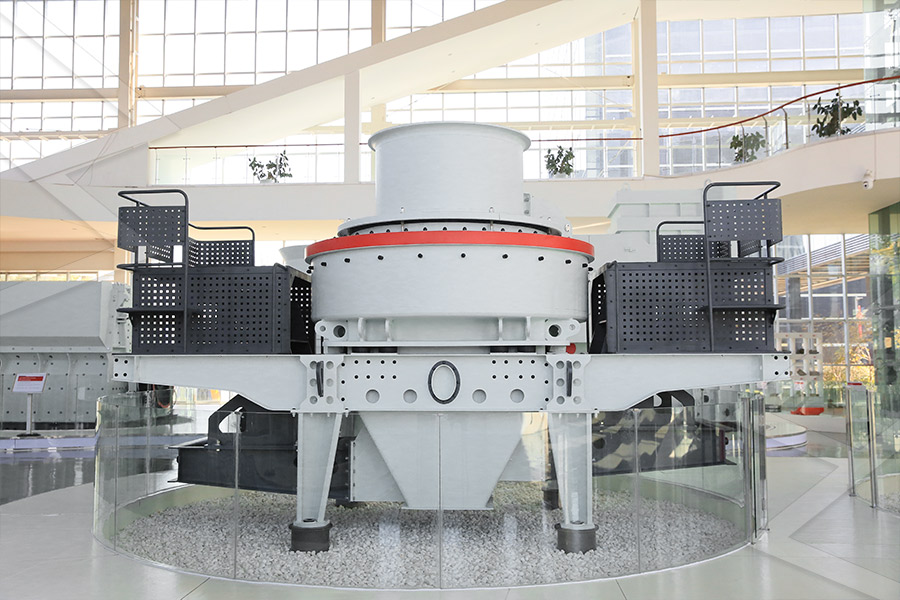

2024年12月9日 Jaw crushers are essential in industries like mining, quarrying, and recycling for primary crushing of hard materials such as rock, gravel, and concrete Their robust design and ability to handle high capacities make them a staple in many operations worldwide Fixed Jaw Jaw Crusher In Mineral Processing Design and Operations (Second Edition), 2016 42 Design of Jaw Crushers Jaw crushers are designed to impart an impact on a rock particle placed Jaw Crusher an overview ScienceDirect Topics2024年10月22日 A jaw crusher is a compression type crusher, usually used as a primary crusher set at the very front of the ore or rock crushing plant to reduce hard rock size Jaw rock crushers are commonly doubletoggle jaw crushers, Jaw Crusher JXSC MineralChina Mineral Crusher wholesale Select 2024 high quality Mineral Crusher products in best price from certified Chinese Mineral manufacturers, Mineral Processing Machine suppliers, Mineral Crusher MadeinChina

Jaw Crusher Mineral Crushing Aggregate

2024年10月31日 Jaw Crusher is widely used to crush materials into medium size in the first crushing process of ore rocks, so your rocks would get be ready for the secondary crushing it had a wide range of suitable materials, such as If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimension Sizes may be given in imperial (inches etc) or metric (millimetre etc)Jaw Crusher Explained saVRee4 天之前 Jaw crusher is a robust size reduction crushing equipment designed to reduce large solid materials into smaller particles, widely used in the quarrying, metallurgical and allied industries Jaw crusher is one of the most commonly Jaw Crusher JXSC Machinery2022年7月14日 MPE single toggle Jaw Crushers are of the overhead eccentric type and incorporate the most recent advances in design, selection of material and method of MPE’s JAW CRUSHERJAW CRUSHER Mineral Process

Stainless Steel Jaw Crusher ZJH minerals

The fixed jaw and swing jaw and other parts contacted with raw materials, of the stainless steel jaw crusher, are made of stainless steel SUS 304 It is widely applied for lab cleaning crushing for the industry such as electronic 2024年7月18日 The Jaw crushers are designed to crush brittle bulk materials of various strength and hardness limit microswitches and an emergency stop button ensure limited access to the drive parts of the crusher and safe Jaw Crushers – Mineral Innovative TechnologiesWorking Principle Jaw crushers reduce rocks or ore by means of compressionThis mechanical pressure is achieved by the crusher's two jaw dies/ jaw plates, one of which is stationary and the other is movableThese two Jaw Crusher (PE Series Primary Crusher) GTEK2024年2月6日 Jaw crushers are truly the bedrock of any material processing work in both the mining and construction worlds They play an essential part in smashing up big, tough chunks of material into smaller bits, preparing them for Understanding Types of Jaw Crusher: A

.jpg)

Crushers: Types, Maintainance, Selection JXSC Mineral

2023年7月7日 Crushers are designed to efficiently break down different materials, including rocks, ores, minerals, concrete, Regular attention and timely lubrication of the friction surface can ensure the jaw crusher’s normal operation and prolong the equipment’s service life The lubricating grease added to the bearing seat is 5070% of the volume Jaw Crushers The Vanguard Series Jaw Crusher represents the very latest in jaw crusher technology Engineered to be the highest capacity jaw crusher on the market, the Pioneer Jaw Crusher will deliver up to 25% more tons per hour than other comparable jaw crushers Pair that with heavyduty flywheels for reduced horsepower requirementsJaw Crushers Mineral Processing Solutions2024年12月16日 A small jaw crusher is a type of jaw crusher that is specifically designed for smallscale operations, laboratories, or where space and capacity constraints exist These crushers are suitable for crushing small amounts of hard materials into smaller, more manageable pieces Laboratories: For sample preparation and testingSmall Jaw Crusher TAYMACHINERY2024年12月16日 A small jaw crusher is a type of jaw crusher that is specifically designed for smallscale operations, laboratories, or where space and capacity constraints exist These crushers are suitable for crushing small amounts of hard materials into smaller, more manageable pieces Laboratories: For sample preparation and testingSmall Jaw Crusher TAYMACHINERY

Jaw Crusher ScienceDirect

2016年1月1日 Designs of different types of jaw crushers such as Blake, Dodge with single and double toggles used for initial comminution of minerals, as received from mines, are described in detail The method of calculating operating variables such as the critical speed, toggle frequency and throw and power consumptions are explained and illustrated with practical examples with Remove Jaw Plates: Begin by loosening and removing the bolts that secure the jaw plates Depending on the model, you may need special tools to handle this Disconnect Power and Lubrication Systems: Detach electrical connections and lubrication lines from the crusherHow to overhaul a jaw crusher? zenithmineralAlsto JC2013 Jaw Crusher; The Alsto JC2013 is a reliable, heavy duty crusher designed for general laboratory applications, ready and able to crush a large variety of sample types quickly and efficiently Mineral Stats Inc PO Box 253 Henderson, CO 806409998 United States Phone: +1 7207898988 Fax: +1 7205065204 : sales Alsto JC2013 Jaw Crusher Mineral Stats2015年6月26日 Gambar 21 Jaw Crusher Terdapat beberapa jenis Jaw crusher yang di gunakan dalam primary crusher diantaranya: a Blake Alat ini menggunakan energi sebesar 225 – 225 Kw Dan memiliki ratarata rasio Makalah pengolahan mineral crushing PDF

MPE’s JAW CRUSHERJAW CRUSHER Mineral Process

2022年7月14日 MPE Jaw Crusher body is fabricated from mild steel The bigger sizes are provided with steel fabricated stress relieved bodies The eccentric shaft of the Jaw Crusher is of accurately machined alloy steel The fly wheels are mounted on the eccentric shaft to provide smooth crushing action, thus eliminating power pulldown One of the fly6 天之前 Jaw Crusher Introduction Jaw crusher has serveral series such as HJ series Jaw Crusher, PE series Jaw Crusher and PEW series Jaw Crusher It is composed of the dynamic and static two crushing chamber jaw plates, simulate the movement of animals to complete material crushing operationsJaw Crusher, Jaw Crusher Manufacturer, Jaw Crusher for Sale6 天之前 Introducing the TAYMA 200250tph Complete Mining Stone Crusher Plant: Engineered for superior stone crushing efficiency This integrated system is designed to crush large stones into highquality aggregates or sand, essential for mining, quarrying, and construction applications Featuring robust jaw crushers, efficient cone crushers, advanced sand making 200250tph Complete Mining Stone Crusher Plant2020年2月14日 Jaw Crusher merupakan suatu mesin atau alat yang banyak digunakan dalam industri dibidang pertambangan, bahan bangunan, kimia, metalurgi dan sebagainya Sangat cocok untuk penghancuran primer dan sekunder dari semua jenis mineral dan batuan dengan kekuatan tekan sekitar 320 MPa, seperti bijih besi,JAW CRUSHER LinkedIn Indonesia

.jpg)

Jaw Crusher – ZJH minerals

Now ZJH minerals jaw crusher is widely adopted in the aggregate, mining and laboratories and some special industries like NdFeB magnetic material, ceramic pigment , metallic oxide, etc The mechanical engineer is focusing on improving the the design of jaw crusher The basic factor to ensure the best performance of the jaw crusher is the best “EASTMAN” single toggle jaw crusher/granulator is suitable for crushing different types of mineral hard mineral featuring the latest technology for bulk material handling This Jaw Crusher is generally used as a primary/secondary crusher in a crushing circuit The jaw crushers are designed for long life service with minimum maintenance JAW CRUSHER2018年3月15日 Therefore, a new innovative jaw crushertype wear tester was designed especially for wear and mineral property research The modular jaws of the developed dual pivoted jaw crusher allows flexible selection of jaw geometry, which is independent of the selectable compressive and sliding movements of the jawsEffects of compression and sliding on the wear and energy MPE series sealed jaw crusher is a special designed complex swing and super fine crushing equipment mainly for the special industry of NdFeB magnetic material, ceramic pigment , metallic oxide, etc ZJH mainly focus on producing and supply laboratory and pilot scale type of ore dressing equipment for Mining and Mineral Processing IndustrySealed laboratory Jaw Crusher – ZJH minerals

mineral processing handbook AusIMM

2021年6月24日 by the machine to be fed, ie, a jaw crusher with a certain receiving opening, or by the size of the hopper opening to be used Feeder width may also be determined by the maximum lump size in the feed, or by a desired depth of material and conveying speed*† STEP 3 Check capacity of feeder selected against the data inA heavy duty jaw crusher with an high reduction ratio and sample throughput The JC2513 Jaw Crusher is one of the fastest fine jaw crushers on the market It ideally suits high production laboratories employing high quality sample Alsto JC2513 Jaw Crusher Mineral Stats2024年12月13日 1Description Laboratory Jaw Crusher:It is applicable to medium and fine crushed materiails for the purposes of laboratory and production and primarily provided as environmental protection equipment for coal, electric PE150*125 Small Laboratory Jaw Crusher for Superior Jaw Crusher engineered for rapid reduction of hard and brittle materials: Quick and easy to clean due to front door access Stepless, reproducible gapsetting by handwheel Easy exchange of jaw plates and side liners Modular Jaw crusher LMC100D LAARMANN

.jpg)

Gyratory VS Jaw Crushers: Advantages Disadvantages

2016年2月28日 The jaw crusher does not lose any of its “newcondition” throw when the babbitt wears in the main, or in the pitman, bearings The jaw crusher will handle sticky,’or dirty feed better than the gyratory, there being no diaphragm below the crushing chamber on which such material can pack Routine maintenance and repair jobs are generally Jaw crusher digunakan dalam berbagai tahapan pengolahan mineral, mulai dari penghancuran awal bijih hingga pemrosesan lanjutan material yang sudah berukuran lebih kecil Dalam industri pertambangan, kemampuannya untuk mengurangi ukuran batu besar menjadi kerikil atau bahkan pasir, merupakan langkah awal yang kritikalMengenal Jaw Crusher, Alat yang Merevolusi Industri The Jaw Crushers Price is a key item within our extensive Mining Crusher selectionSourcing mining crushers wholesale offers cost savings due to bulk purchase prices, quality assurance through direct relationships with suppliers, and customization options to Jaw Crushers Price MadeinChina2024年12月17日 Feeding Size: 01200mm Capacity: 01200 TPH Application: B arite, manganese ore, granite, limestone, dolomite, river pebbles, iron ore, copper ore, basalt, gold ore, etc, Standard Modular Crushing And Screening Plants: Jaw, cone, impact crusher station, sandmaking machine station, screening machine station Modular crushing plants can meet your Modular Crushing Screening System JXSC Mineral

.jpg)

Jaw Crusher Mineral Crushing Aggregate Processing

2024年10月31日 Application Field Jaw Crusher is widely used to crush materials into medium size in the first crushing process of ore rocks, so your rocks would get be ready for the secondary crushing it had a wide range of suitable materials, such as granite, marble, basalt, limestone, quartz, pebble, iron ore, copper ore and so on the jaw crusher is applicated in mining, 2024年11月17日 The first is the wellknown traditional jaw crusher range that is designed for stationary as well as mobile applications (PEV80, PEV100, PEV 3054, PEV110, PEV125, PEV140, PEV145, PEV160, PEV200) The second range is designed specifically to meet the needs of small to mediumsized mobile crushing (PEV96, PEV106, PEV116) AF Minerals PEV Series Jaw Crusher AF Minerals EquipmentChina mineral crusher,a world leading heavy machine company serving metallurgy cement , construction , refractory materials and ceramic industry and other sectors Different jaw crusher designs will operate slightly differently, but how they work is similar across the board All jaw crushers reduce large sized rocks ore, or other materials Home CHINA MINERAL CRUSHER2024年7月18日 The Jaw crushers are designed to crush brittle bulk materials of various strength and hardness limit microswitches and an emergency stop button ensure limited access to the drive parts of the crusher and safe Jaw Crushers – Mineral Innovative Technologies

Jaw Crusher (PE Series Primary Crusher) GTEK

Working Principle Jaw crushers reduce rocks or ore by means of compressionThis mechanical pressure is achieved by the crusher's two jaw dies/ jaw plates, one of which is stationary and the other is movableThese two 2024年2月6日 Jaw crushers are truly the bedrock of any material processing work in both the mining and construction worlds They play an essential part in smashing up big, tough chunks of material into smaller bits, preparing them for Understanding Types of Jaw Crusher: A 2023年7月7日 Crushers are designed to efficiently break down different materials, including rocks, ores, minerals, concrete, Regular attention and timely lubrication of the friction surface can ensure the jaw crusher’s normal operation and prolong the equipment’s service life The lubricating grease added to the bearing seat is 5070% of the volume Crushers: Types, Maintainance, Selection JXSC MineralJaw Crushers The Vanguard Series Jaw Crusher represents the very latest in jaw crusher technology Engineered to be the highest capacity jaw crusher on the market, the Pioneer Jaw Crusher will deliver up to 25% more tons per hour than other comparable jaw crushers Pair that with heavyduty flywheels for reduced horsepower requirementsJaw Crushers Mineral Processing Solutions

Small Jaw Crusher TAYMACHINERY

2024年12月16日 A small jaw crusher is a type of jaw crusher that is specifically designed for smallscale operations, laboratories, or where space and capacity constraints exist These crushers are suitable for crushing small amounts of hard materials into smaller, more manageable pieces Laboratories: For sample preparation and testing2024年12月16日 A small jaw crusher is a type of jaw crusher that is specifically designed for smallscale operations, laboratories, or where space and capacity constraints exist These crushers are suitable for crushing small amounts of hard materials into smaller, more manageable pieces Laboratories: For sample preparation and testingSmall Jaw Crusher TAYMACHINERY2016年1月1日 Designs of different types of jaw crushers such as Blake, Dodge with single and double toggles used for initial comminution of minerals, as received from mines, are described in detail The method of calculating operating variables such as the critical speed, toggle frequency and throw and power consumptions are explained and illustrated with practical examples with Jaw Crusher ScienceDirectRemove Jaw Plates: Begin by loosening and removing the bolts that secure the jaw plates Depending on the model, you may need special tools to handle this Disconnect Power and Lubrication Systems: Detach electrical connections and lubrication lines from the crusherHow to overhaul a jaw crusher? zenithmineral

.jpg)

Alsto JC2013 Jaw Crusher Mineral Stats

Alsto JC2013 Jaw Crusher; The Alsto JC2013 is a reliable, heavy duty crusher designed for general laboratory applications, ready and able to crush a large variety of sample types quickly and efficiently Mineral Stats Inc PO Box 253 Henderson, CO 806409998 United States Phone: +1 7207898988 Fax: +1 7205065204 : sales